Powerful Solutions for Machine Vision Applications

Spectra PowerBox 3000F: Industrial Box-PC Series with Alder Lake Processors

Quality control through component inspection and object identification and tracking in production processes are

just two examples of machine vision applications in industrial environments. Embedded PCs such as the Spectra

PowerBox 3000F with high computing power and ultra-fast interfaces for modern camera systems play a key role in

these applications.

Read More

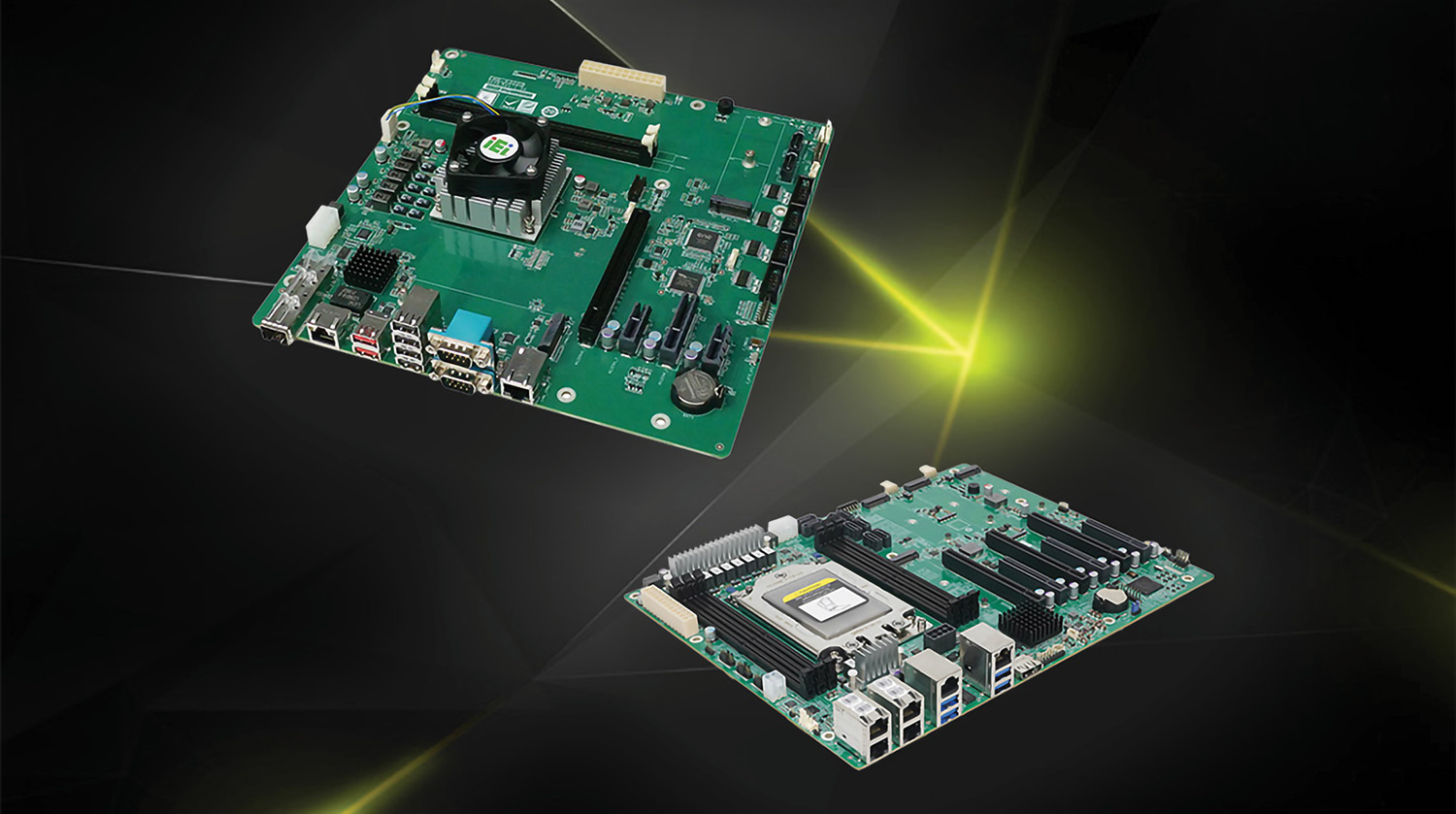

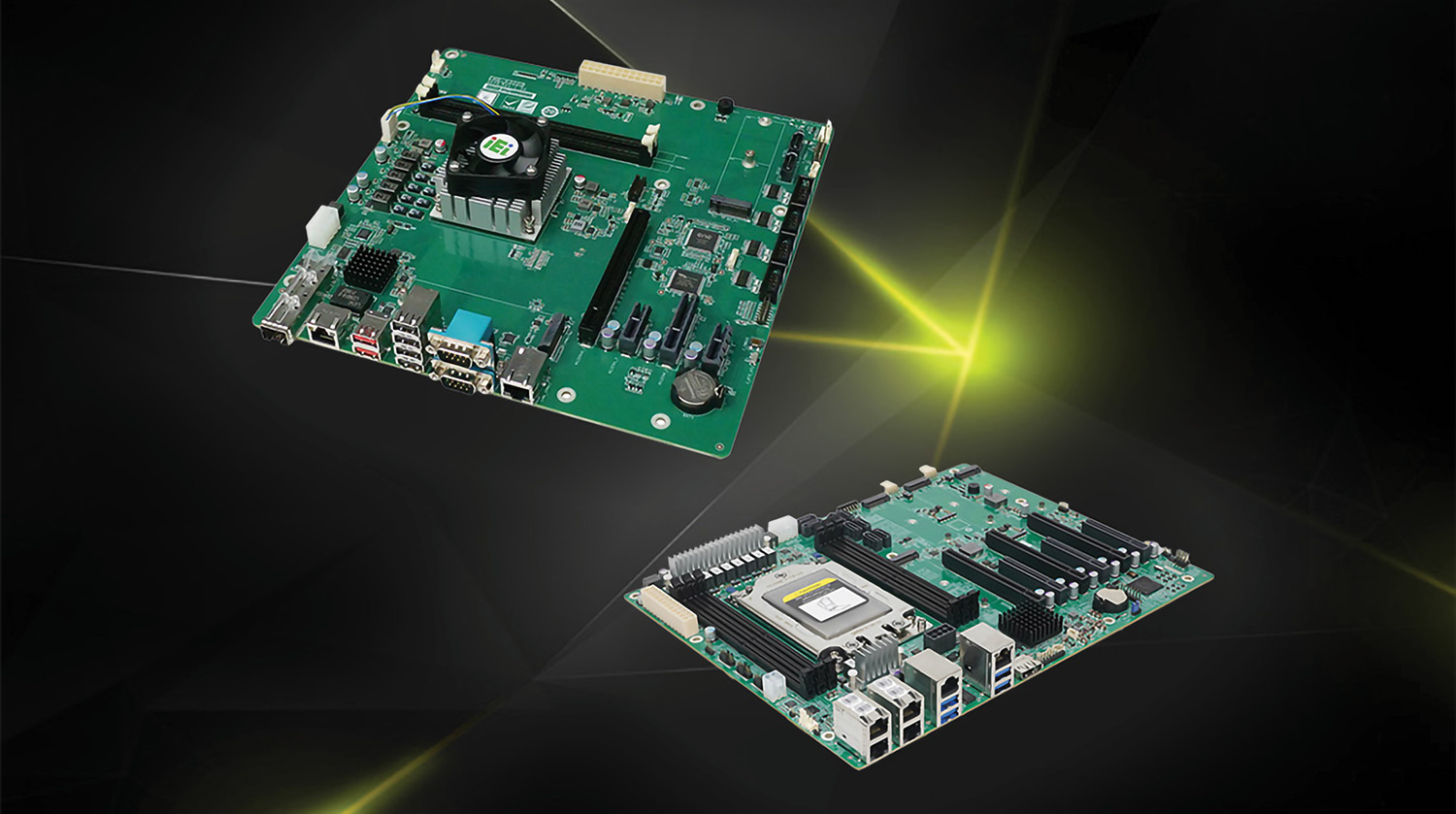

Ultra Power in Mini-ITX format

Spectra LV-6716H7: Embedded board for compact image processing solutions

“We need a compact solution to capture and process image data on the machine.” Image processors, AI users and

IPC manufacturers know these or similar requirements well enough. And the solution usually starts with the

selection of the right computer platform.

Read More

Single-board computer with AMD processors

AMD makes its way into single-board products from ICP Deutschland. The company has expanded its portfolio with

two powerful AMD solutions. The IMB-V3000 is a Micro ATX mainboard that is equipped with a built-in AMD Ryzen

Embedded V3000 processor. The IMBAX-SP6 is an industrial ATX mainboard that was developed specifically for

server applications. Both single-board computers can be used, for example, in industrial automation, vision

applications, medical imaging and traffic monitoring.

Read More

Ideally suited for industrial environments

Spectra PowerBox 630: Powerful and flexible box PC

In industrial sectors such as automation, logistics and manufacturing, high temperatures, vibrations, dust and

dirt are part of everyday life. They require reliable box PCs that can run under industrial conditions, monitor

production processes and control machines efficiently.

Read More

Maximum expandability and highest computing power

Spectra WS-6000 series: High-end workstation for image processing, data analysis and AI applications

Companies working in areas such as image processing, machine learning, simulations and data analysis have

special requirements for the industrial computers they use. These must not only offer high computing power but

must also be flexibly expandable and extremely reliable.

Read More

Vision - the world's leading trade fair for machine vision

Experience innovative technologies such as artificial intelligence, embedded vision and the close integration of image processing and automation

image processing and automation - for the smart factory of tomorrow and for constantly growing non-industrial applications.

Read More

HG-F1 – Laser measurement sensor for ranges of up to 3 m

The HG-F uses TOF technology to reliably detect at distances of up to 3 m. This means that the sensor can also

be installed at some distance from the object to be measured so as not to disturb employees. The movement radius

of cobots or robot arms can also be kept clear in this way.

Read More

3D CAD Visualisation in AR and VR

XR engineering software Hololight Space supports Magic Leap 2 and Meta Quest 3

At Hannover Messe, the AR/VR expert Hololight will be showcasing

the new version of its 3D CAD visualisation software Hololight Space.

Read More

Automation solutions from a single source

From laser measurement sensors and servo drives to laser marking systems: Panasonic Industry offers innovative,

high-precision products and customized services for a wide range of industries.

Read More

Bin picking made easy

The Zivid Two L100 industrial 3D camera enables more productive bin picking with deeper reach, enabling extended

grippers to empty larger, deeper bins.

Read More

Factory Planning with Augmented Reality

Future Technology used in Everyday Work. CAD models as holograms. Modifiable and collaboratively editable.

Augmented Reality (AR) is expected to revolutionize workflows in factory planning. At BASF, the world’s largest

chemical company, the use of AR already shows great potential.

Read More

Contactless angle measurement with camera‑based encoders

Visevi Robotics offers novel vision-based encoders ViseJoint now for generic angular measurement applications

without sensors on the joint. Measurement of one or multiple joints is performed remotely, using a computer

vision software and a camera that looks onto the joints from a distance. The solution can be used for smart

robots.

Read More

Robotron and Kontron simplify computer vision

Many manufacturing companies still find it difficult to get started with Artificial Intelligence (AI), not least

because of the complex hardware selection. In the new AI workstation, Robotron and Kontron now combine two of

their innovative solution approaches for the uncomplicated and fast application of computer vision. The

multi-purpose AI workstation enables training, execution and inference of algorithms for a wide range of models

and frameworks. The standardized approach covers up to 90...

Read More

Industrial Panel PC in IP66/69K stainless steel housing

Spectra-Panel Z-Series meets requirements of the food, pharmaceutical and medical industries.

Hygiene requirements are particularly high in the food, pharmaceutical and medical industries. Since the spread

of particles, germs and other contaminants must be prevented at all costs, materials are used in the production

process whose contamination potential is as low as possible.

Read More

The power pack for automation

Spectra PowerBox 3000C – Mini‑PC with Coffee Lake Power. High computing power, extensive expansion options as well as the compact design have made the mini PCs of the

Spectra PowerBox 3000 series a real 19-inch alternative since the first generation. Due to these

characteristics, they are recommended, for example, for use in machine and system control.

Read More

Image processing in a new dimension

Spectra PowerBox 5000: Scalable high-end GPU computing system. Modern processes in industrial AI and machine vision are closely linked to image processing. This requires

industrial PC systems with CPU and GPU performance large enough to process the tasks in real time.

Read More

AI plug-in card with Coral Edge TPUTM for retrofitting

With the Mustang-T100-T5 ICP Germany expands its portfolio of AI accelerator cards and brings another

possibility to extend existing systems with AI functionalities.

Read More

Future-proof visualisations for IIoT applications

Machinery and plants as well as production processes generate a continual flow of data. Companies that are able

to generate added value from this data will be able to enjoy success in the future. However, the large amount of

generated data must be easily accessible to the machine operator via a HMI (Human Machine Interface). With the

u-create PROCON-WEB SCADA software tool and PROCON-WEB Embedded System, Weidmüller provides visualisation

solutions with...

Read More

AI accelerator cards for AIoT edge computing

At the edge, the use of GPU-based systems for AI computing is usually not practical due to the physical size of

the inference system, the high-power consumption and the unfavourable price-performance ratio. The Mustang AI

accelerator card series from ICP Germany offers new solutions for edge computing in the field of Artificial

Intelligence of Things (AIoT).

Read More

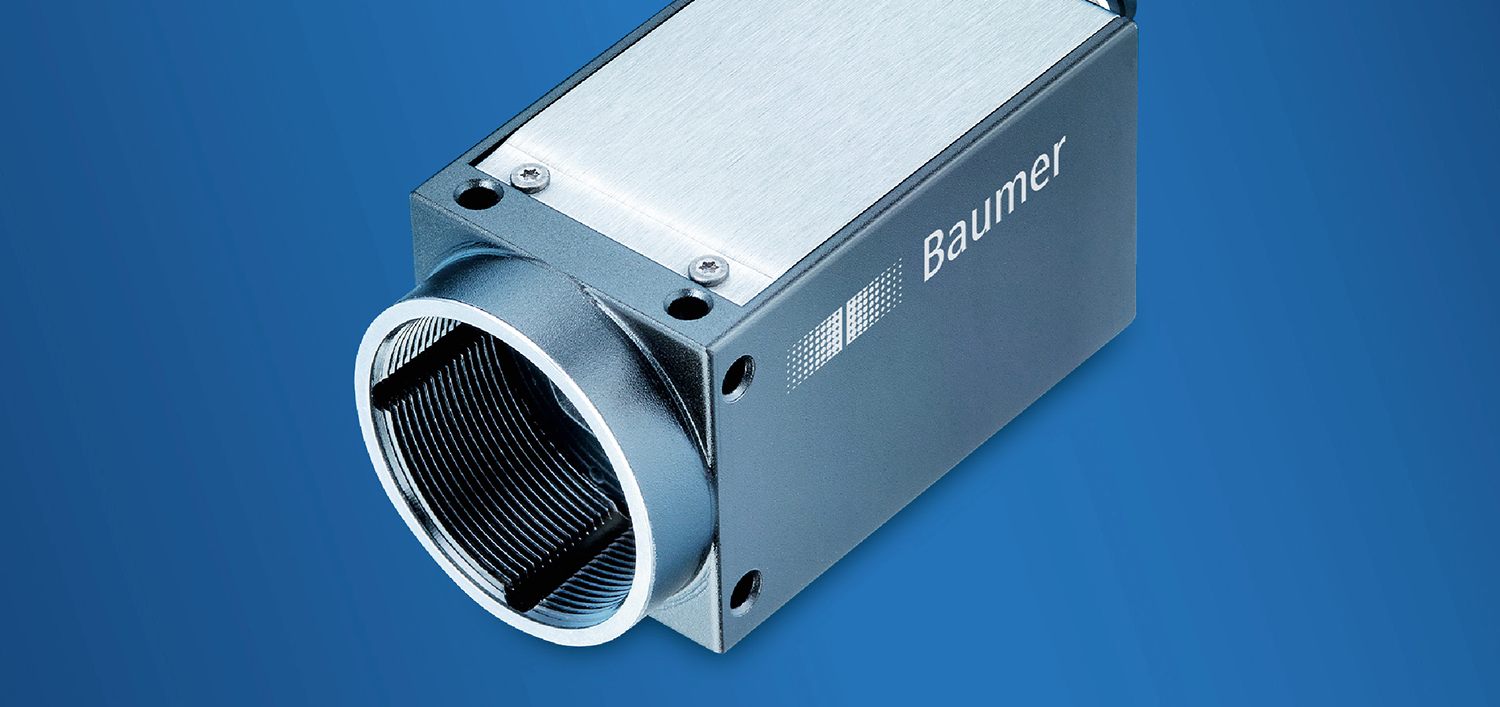

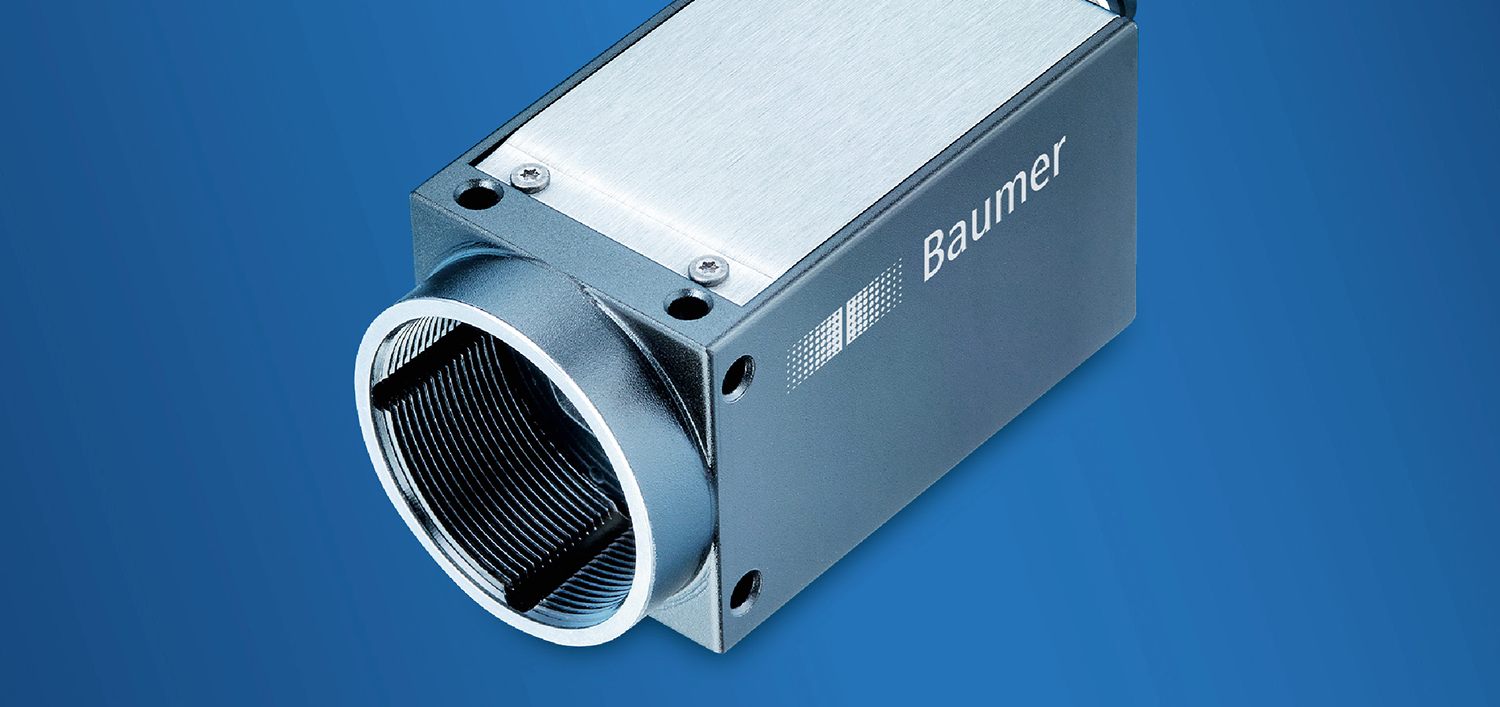

Ready for AI

Powerful, freely programmable smart cameras with NVIDIA Jetson modules. Baumer presents the AX smart cameras,

its first industrial-grade smart cameras that combine the market-leading NVIDIA Jetson modules with powerful

Sony CMOS sensors to create a compact, flexible, and freely programmable image processing platform for

AI‑applications.

Read More

Small pixels for higher image quality

Compact 29×29 mm industrial cameras with Sony Pregius S sensors up to 24 MP. Baumer is expanding its CX series

with the 4th Sony CMOS sensor generation Pregius S with up to 24 megapixel resolution. Thanks to a pixel size of

mere 2.74 µm and backside illumination pixel architecture, the camera has a very compact design (29 × 29 mm) and

offers very high resolutions with excellent image quality and improved sensitivity for stable image evaluations.

Read More

Image processing in a new dimension

Spectra PowerBox 5000: Scalable high-end GPU computing system. Modern processes in industrial AI and machine

vision are closely linked to image processing. This requires industrial PC systems with CPU and GPU performance

large enough to process the tasks in real time.

Read More

Human Digital Twin: The digital counterpart to the human worker

Wearables from ProGlove make humans a driving force of Industry 4.0 and digital transformation. The Digital Twin

is a digitized model that maps the physical characteristics of a production environment as well as the

processes. But this mapping has its limitations, as it only includes data from machines and not from humans. At

the same time, human employees will continue to play an important role in the Fourth Industrial Revolution, also

known as Industry 4.0. The challenge lies in combining the...

Read More

Cameras, image sensors, photodiodes based on InGaAs

Hamamatsu Photonics provides InGaAs solutions covering the visible (VIS), near infrared (NIR), and short

wavelength infrared (SWIR) regions. Our solutions fulfill different applications including spectrometers for

spectrometry, scientific cameras for microscopy, and machine vision for industrial imaging. Also, we provide

driver modules and evaluation boards to decrease your design time. Customizations are available for specific

applications and requirements.

Read More