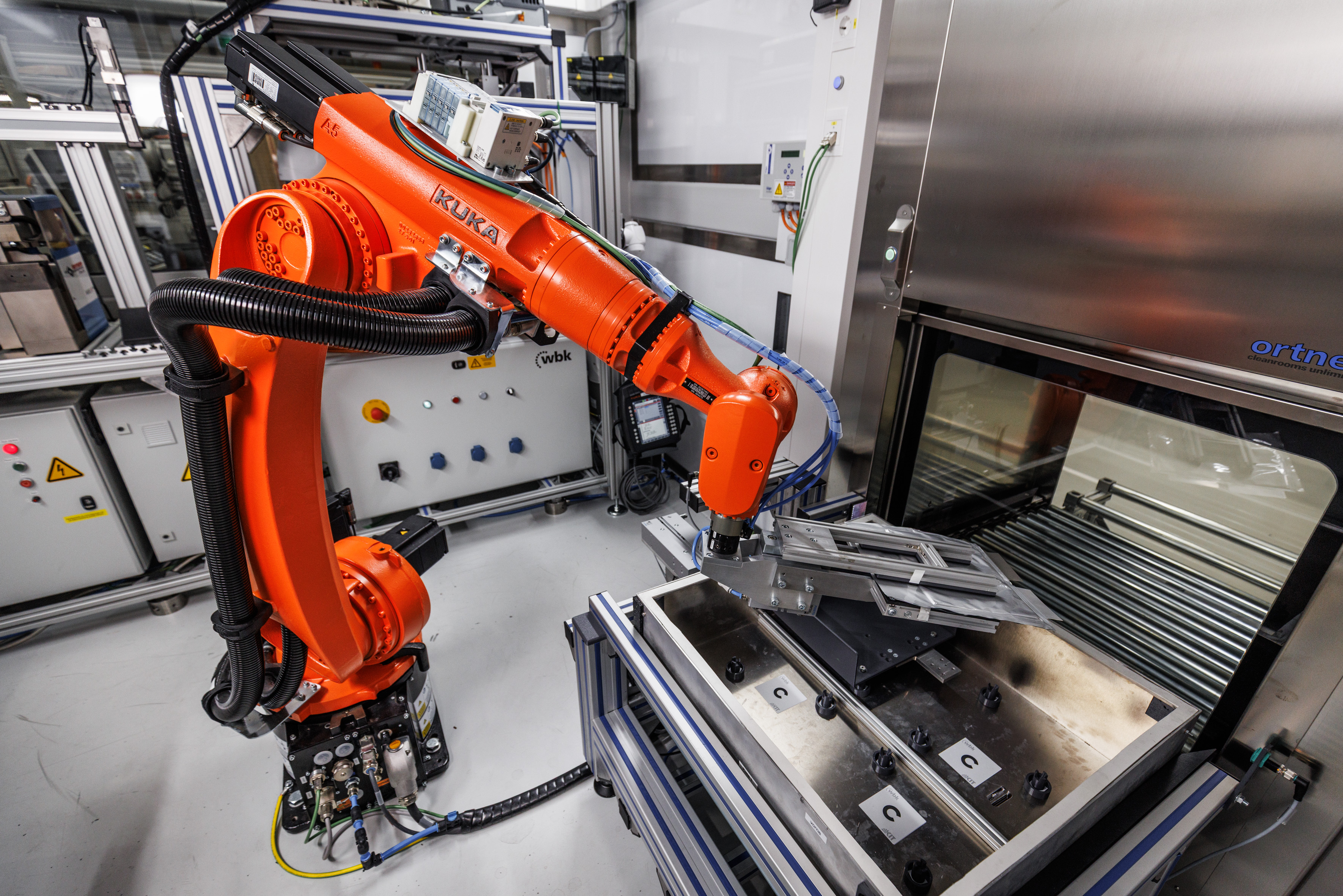

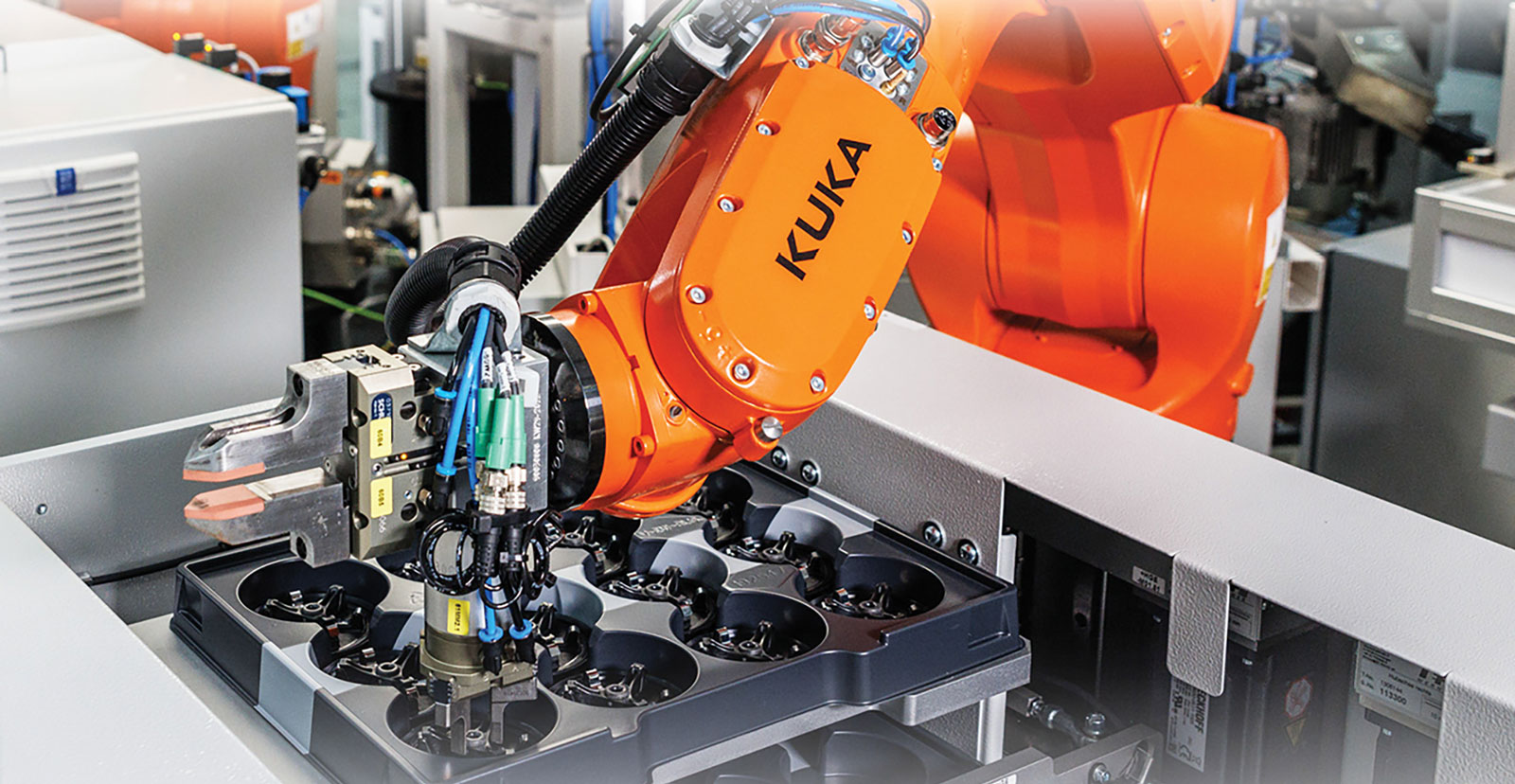

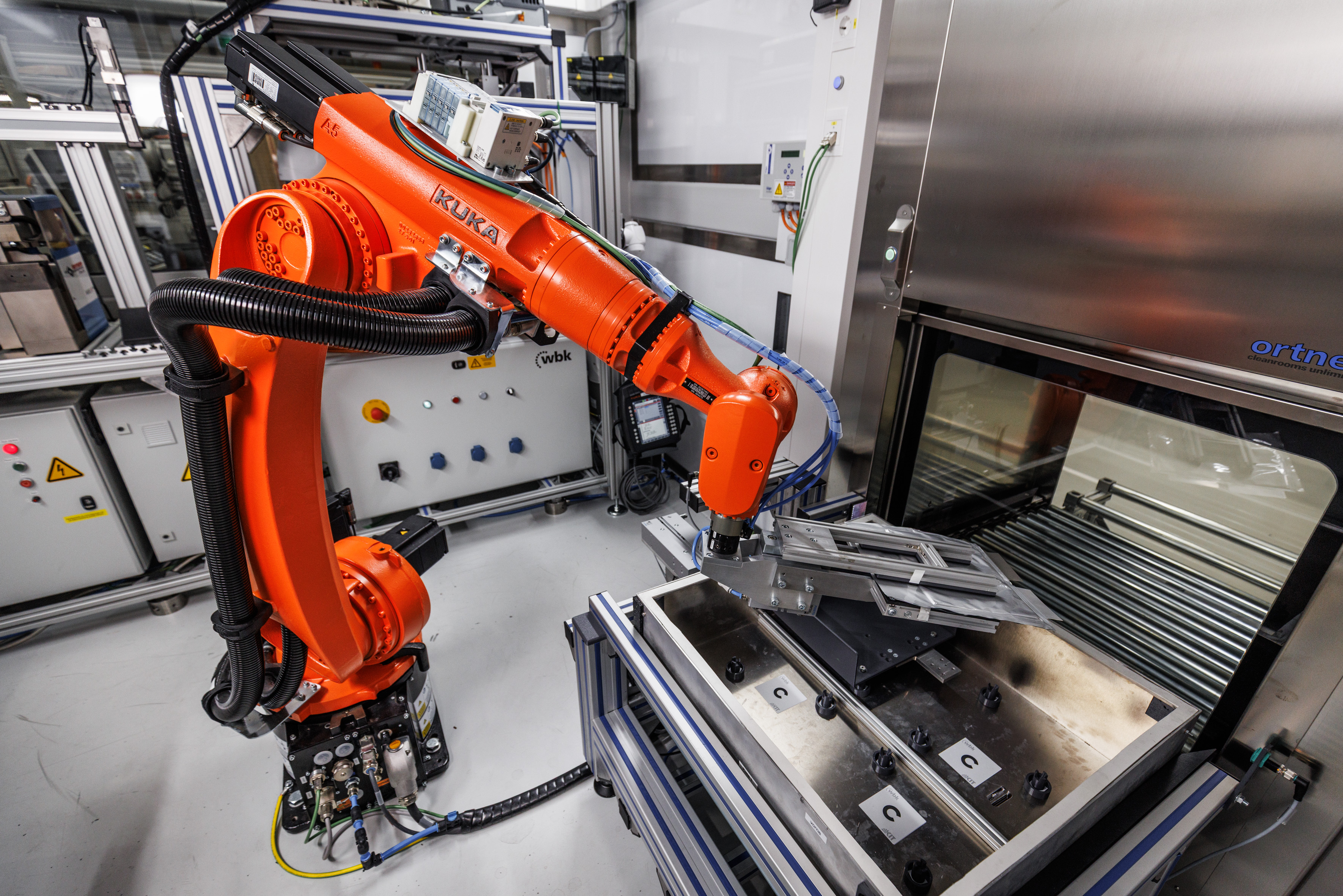

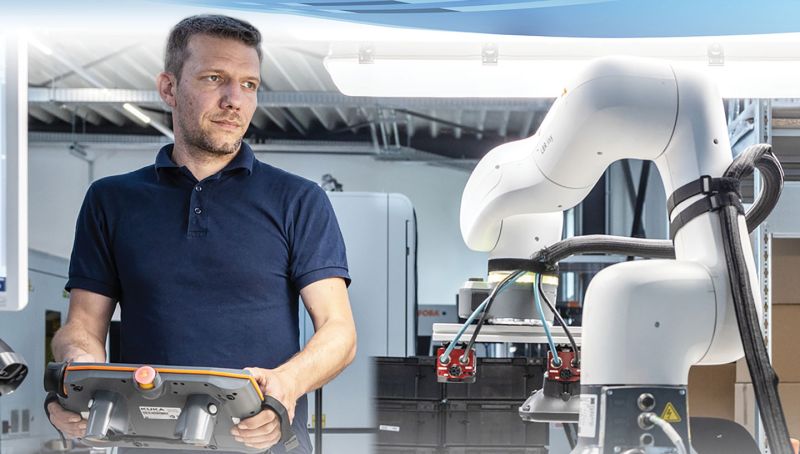

Agile cell production with KUKA robots

From e-mobility to communication and from medical technology to smart tools and household appliances, industry

needs more and more battery cells. However, their production in gigafactories consumes enormous amounts of

energy. In addition, the large production lines are very inflexible. A possible alternative has now been

successfully trialed at the wbk Institute of Production Engineering at KIT. The approach: process containment in

mini-environments. Robots from KUKA fill one of the main roles!

Read More

Made to grow your imagination – Drive Systems for agricultural robotics

Promising solutions for increasing efficiency in agriculture are offered by agricultural robotics. Suitable

drive systems need to be as compact as possible, like the flat DC-micromotors of the BXT series from FAULHABER.

For applications with major fluctuations in temperature and under the harshest conditions, the extremely robust

motors of the CXR family are ideally suited. Incremental encoders and compact drive electronics enable dynamic

and highly positioning when sowing, replanting or harvesting.

Read More

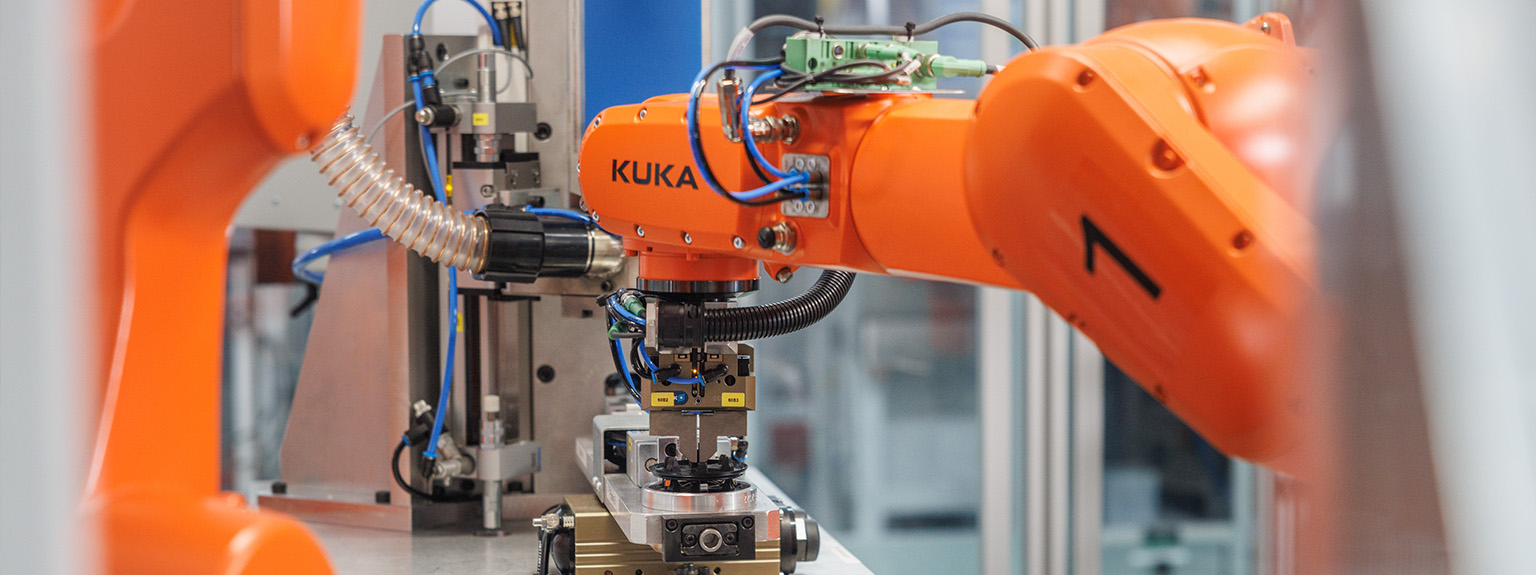

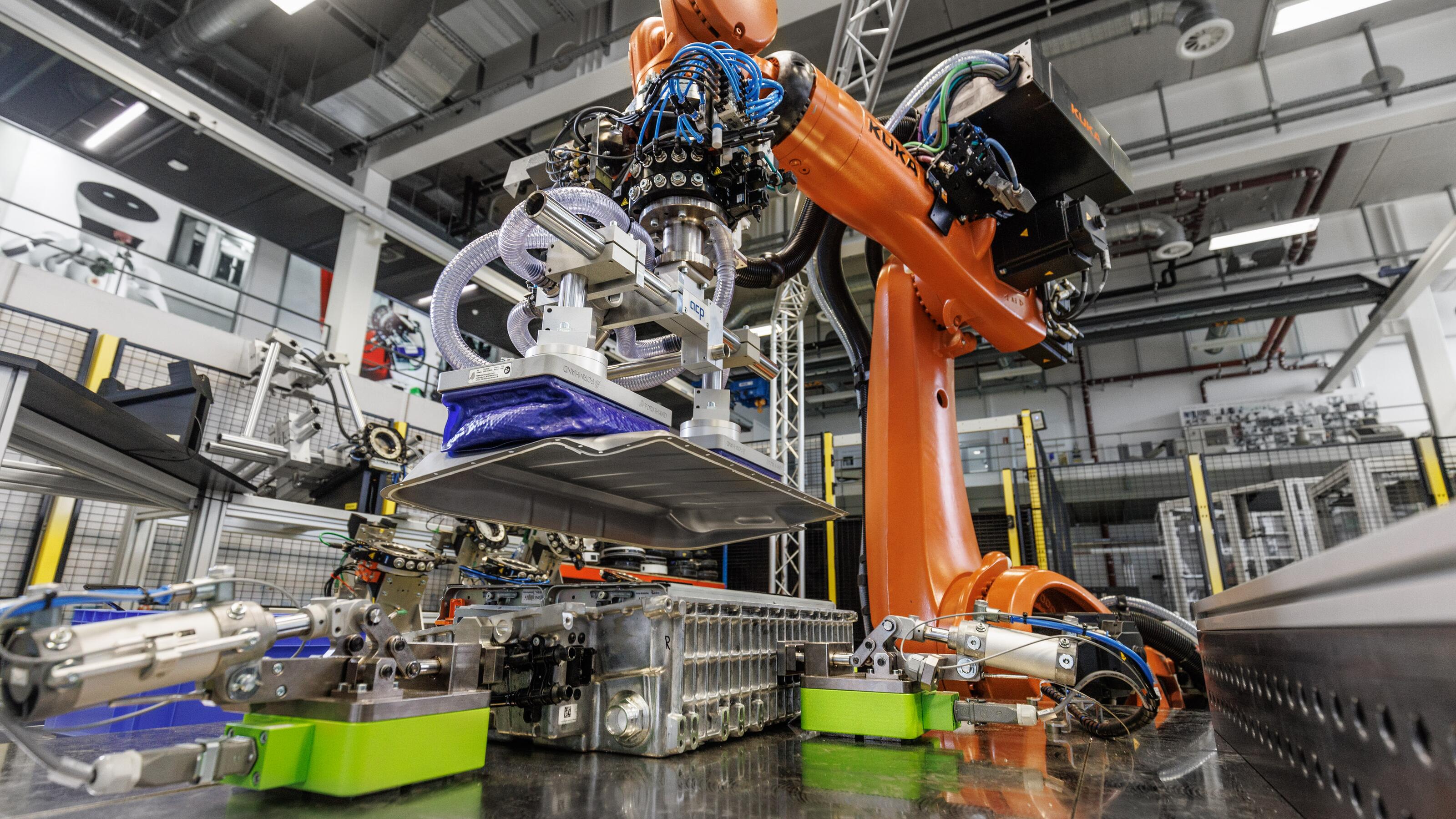

Recycling makes e-mobility more sustainable

KUKA robots disassemble battery systems

The business of electric cars is booming – but what happens to the tons of used batteries? Fraunhofer Institute

for Manufacturing Engineering and Automation has successfully tested how industrial battery disassembly works

using the KR QUANTEC robot. The goal: make the use of electric cars even more sustainable.

Read More

Mobile AI

Embedded PCs with Nvidia Jetson chips for autonomous mobile robots (AMR) and automated guided vehicles (AGV)

ICP Germany has a range of powerful computers designed specifically for AI and machine learning applications.

With their compact form factor and high computing power, they are ideal for mobile use and edge computing

applications. The FLYC-300 embedded PC is so light that it is even suitable for drones.

Read More

Compact Edge AI embedded systems for autonomous mobile robots

Designed for use in the smallest of spaces, ICP Germany is launching the NRU-154PoE and the NRU-156U3, two

embedded systems with a flattop cooling design. The cooling design enables use in particularly confined spaces,

such as in Automated Guided Vehicles (AGV) or Autonomous Mobile Robots (AMR).

Read More

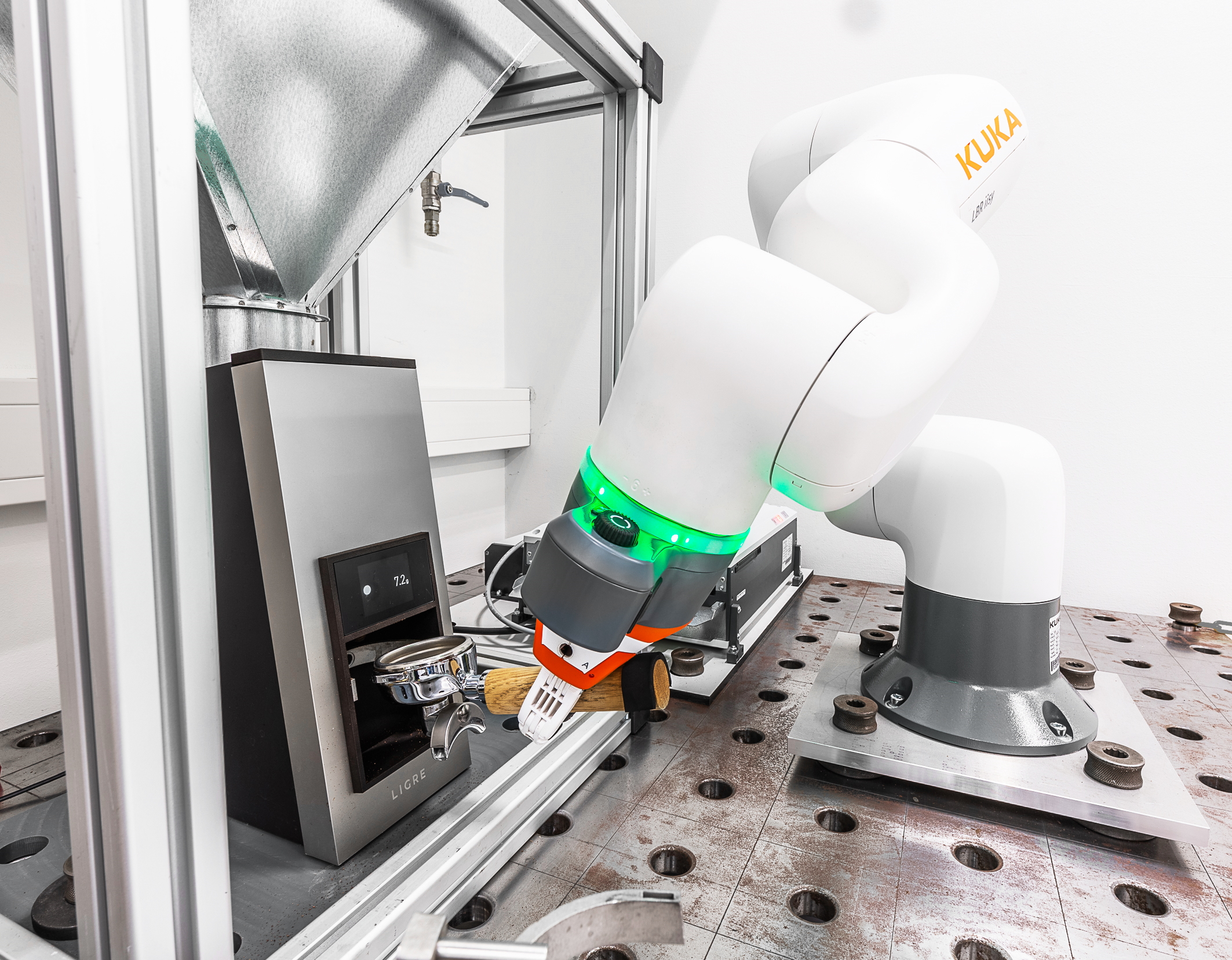

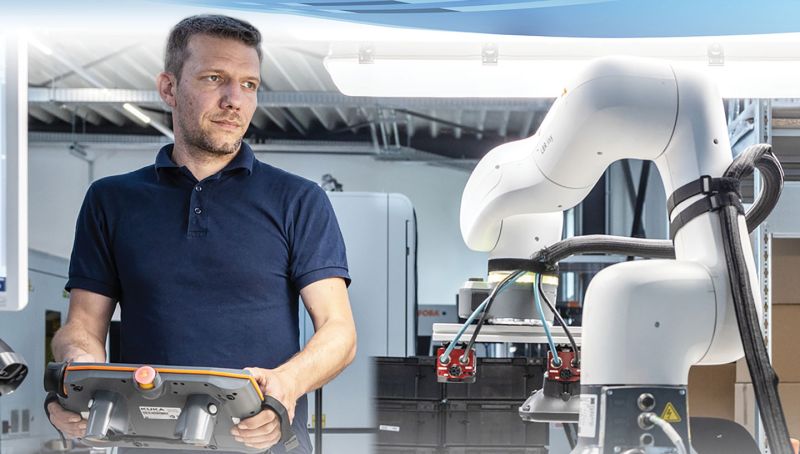

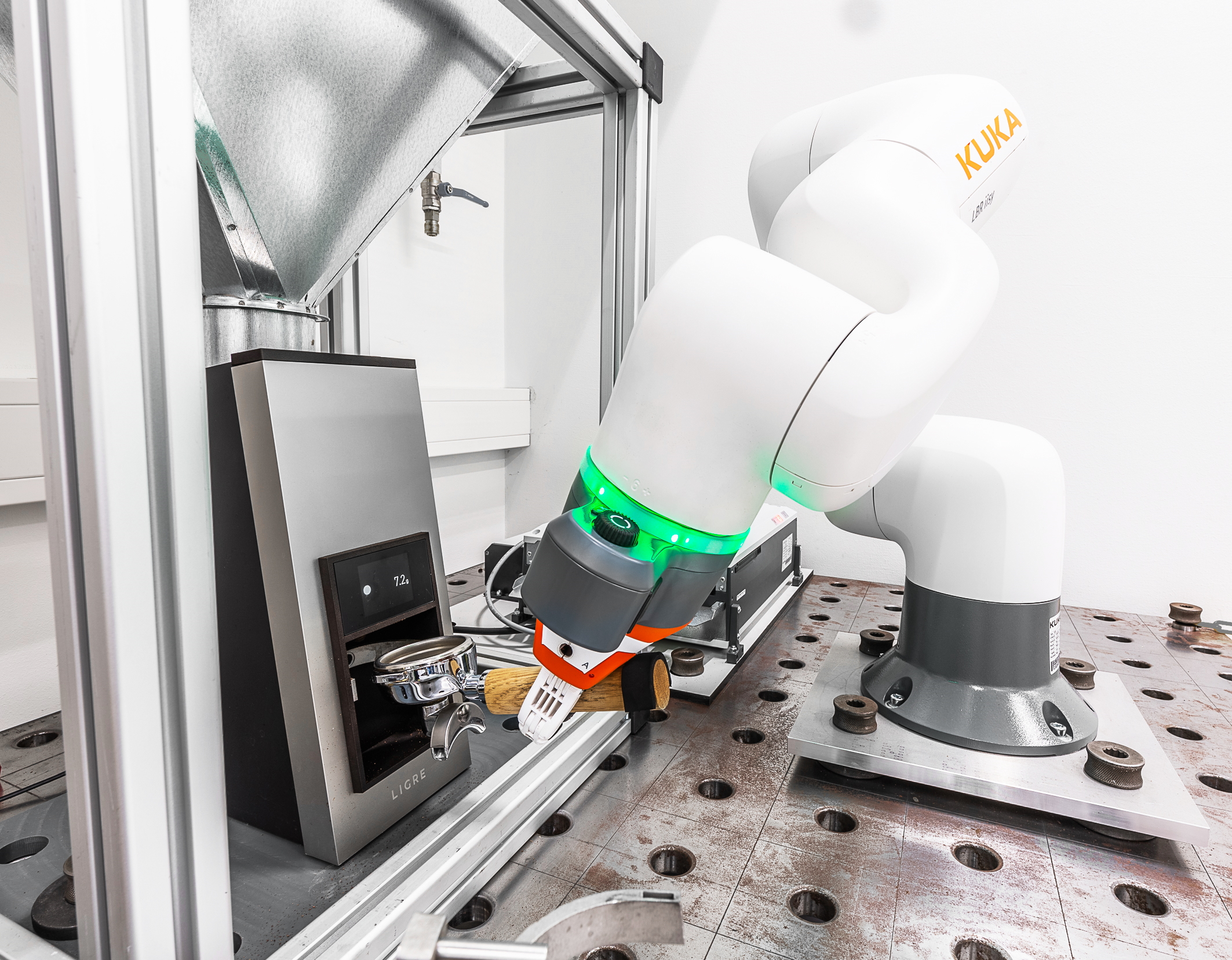

Robot checks coffee grinder: KUKA LBR iisy cobot in quality assurance

LIGRE, a brand launched by Gronbach, is conquering the consumer goods industry with a fresh feature for

household coffee grinders: grinding coffee to the exact gram. Previously reserved for coffee machines that were

designed for the food service industry, Gronbach's development engineers relied on the support of the LBR iisy

cobot from KUKA. To test for quality control, they put the new grinder's durability and compliance with the

preset coffee weight through thorough examination.

Read More

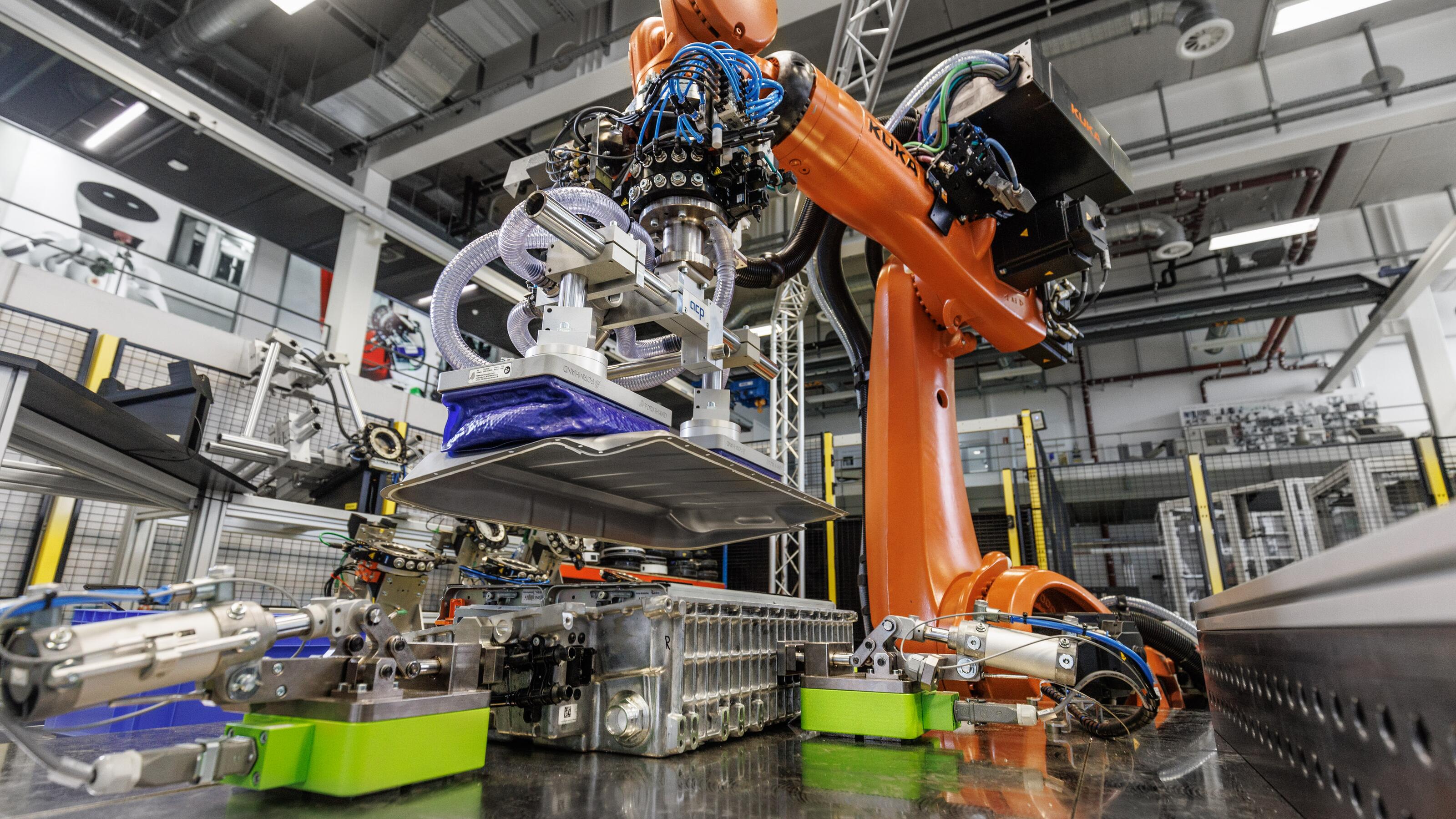

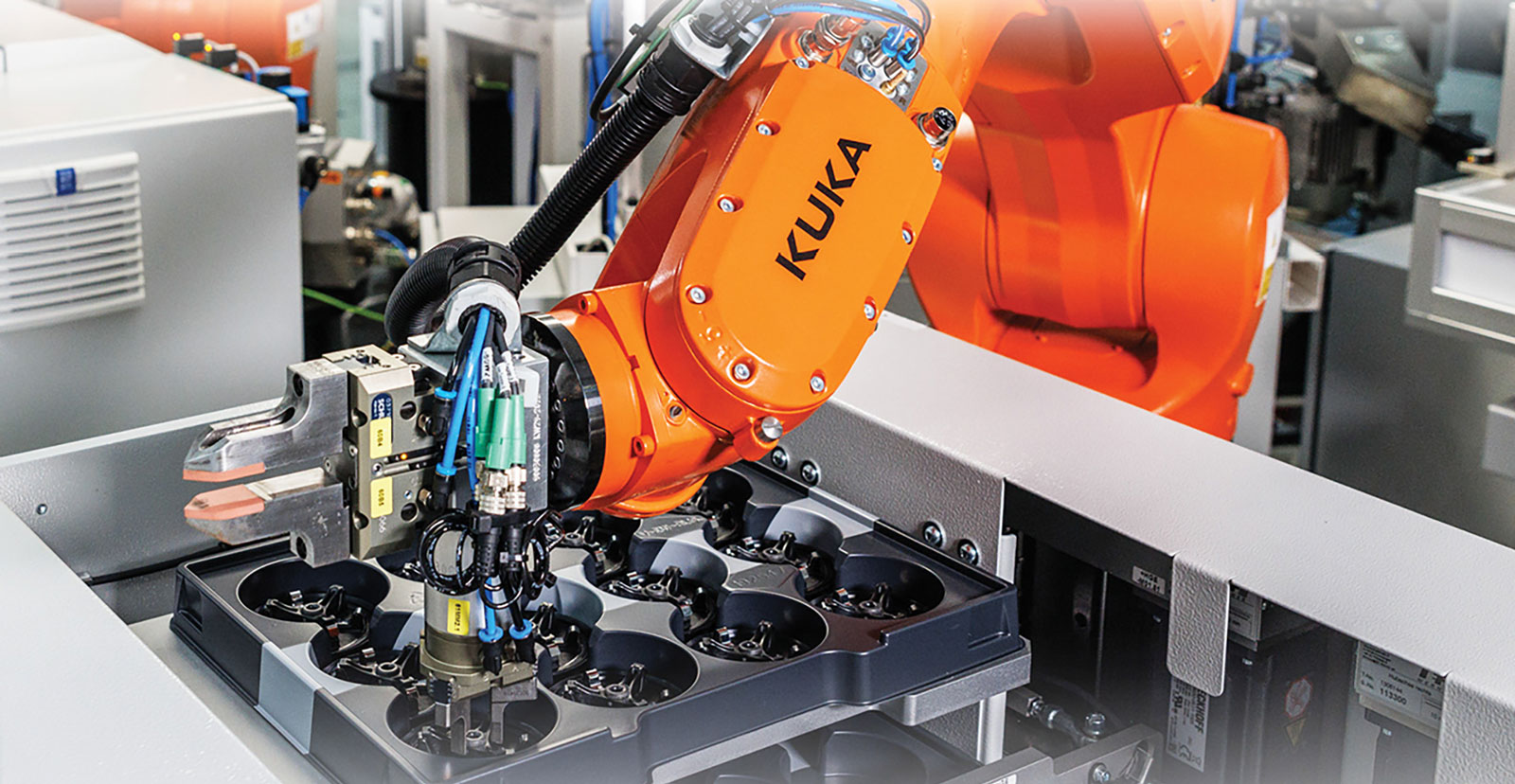

Automated production strengthens e-mobility

KUKA robots in the production of safety valves for batteries

The boom in e-mobility is causing a significant demand for batteries and the parts they contain. This is being

felt by automotive supplier Hugo Benzing from Korntal-Münchingen near Stuttgart, which produces battery bursting

discs, among other things. The valves reduce the pressure in the battery in the case of thermal overheating and

thus make a significant contribution to the safety of electric cars. The production of the valves is challenging

and highly synchronized – and therefore ideal for automation solutions.

Read More

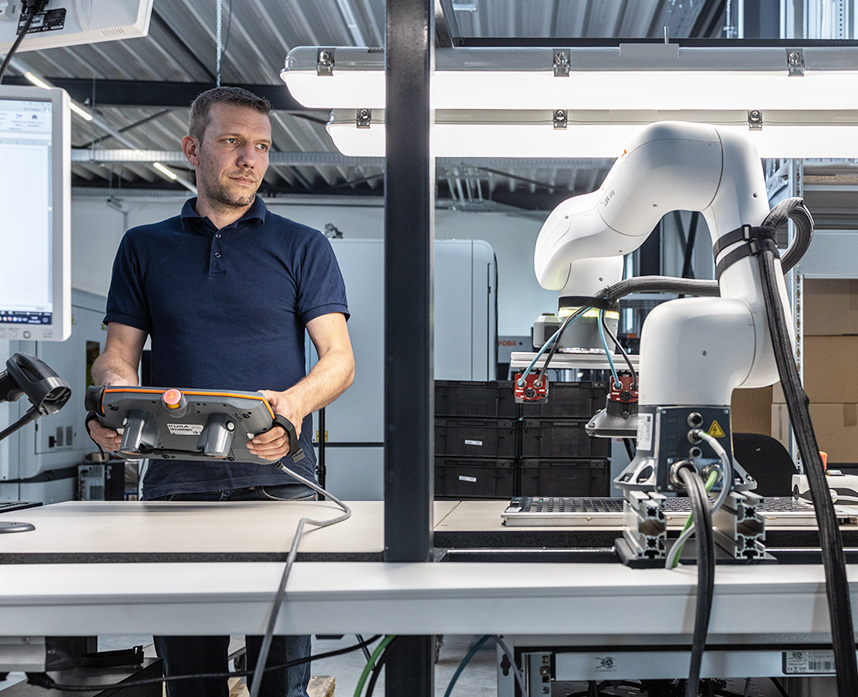

Automation in small and medium-sized enterprises

Mastering tomorrow's challenges today.

From a shortage of skilled workers to high energy prices and supply bottlenecks: Small and medium-sized

enterprises are currently facing major challenges. In the future, the situation might even become worse.

Automation is not the answer to all challenges faced by SMEs, but it is the answer to many. With cobots,

industrial robots and software that fits the industry, companies increase their efficiency, add value to jobs,

and remain competitive.

Read More

Innovation for limited spaces: fanless embedded PC BOXER‑6451-ADP Pocket-Sized Powerhouse

Innovation for limited spaces: fanless embedded PC BOXER‑6451-ADP. BRESSNER Technology, a leading provider of

embedded solutions, unveils the BOXER-6451-ADP, a fanless embedded PC specifically designed for

space-constrained environments in collaboration by partnered manufacturer AAEON Inc. With its exceptional

performance and compact size, this embedded PC offers the ideal solution for applications in the fields of AMR

(Autonomous Mobile Robot), kiosk, and intelligent manufacturing.

Read More

Bin picking made easy

The Zivid Two L100 industrial 3D camera enables more productive bin picking with deeper reach, enabling extended

grippers to empty larger, deeper bins.

Read More

Fuzzy Logic makes robotics agile

Programming of a laser stripper during operation by operators without software know-how. MBDA, a leading

European aerospace manufacturer, wanted to robotise certain processes in small series or even single unit

production, by allowing an operator with no programming skills to teach the robotic system, in just a few

seconds, the process to be carried out, and then to execute the cycle with complete confidence without human

supervision. Fuzzy Logic's Repplix™ application software module addresses...

Read More

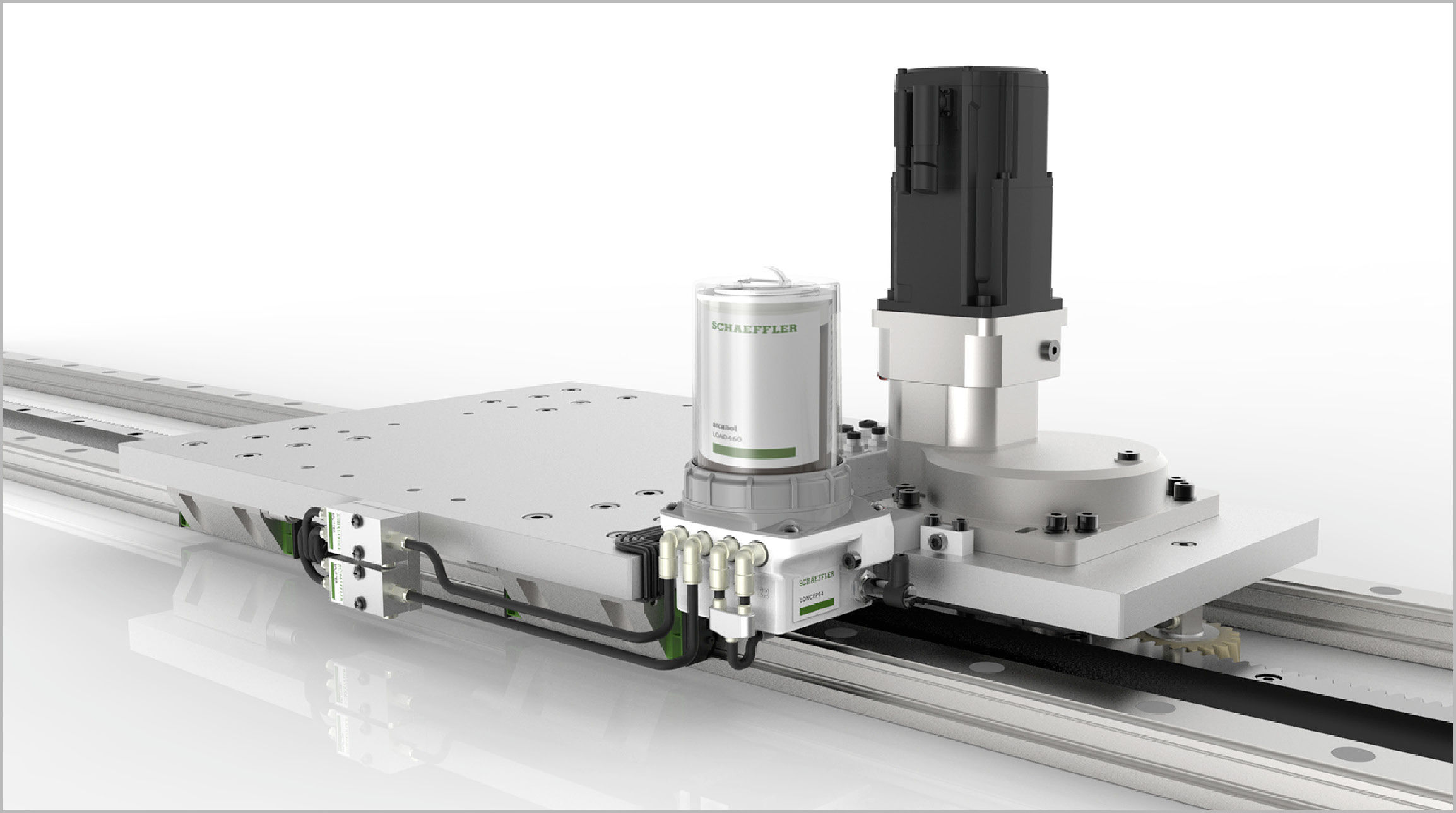

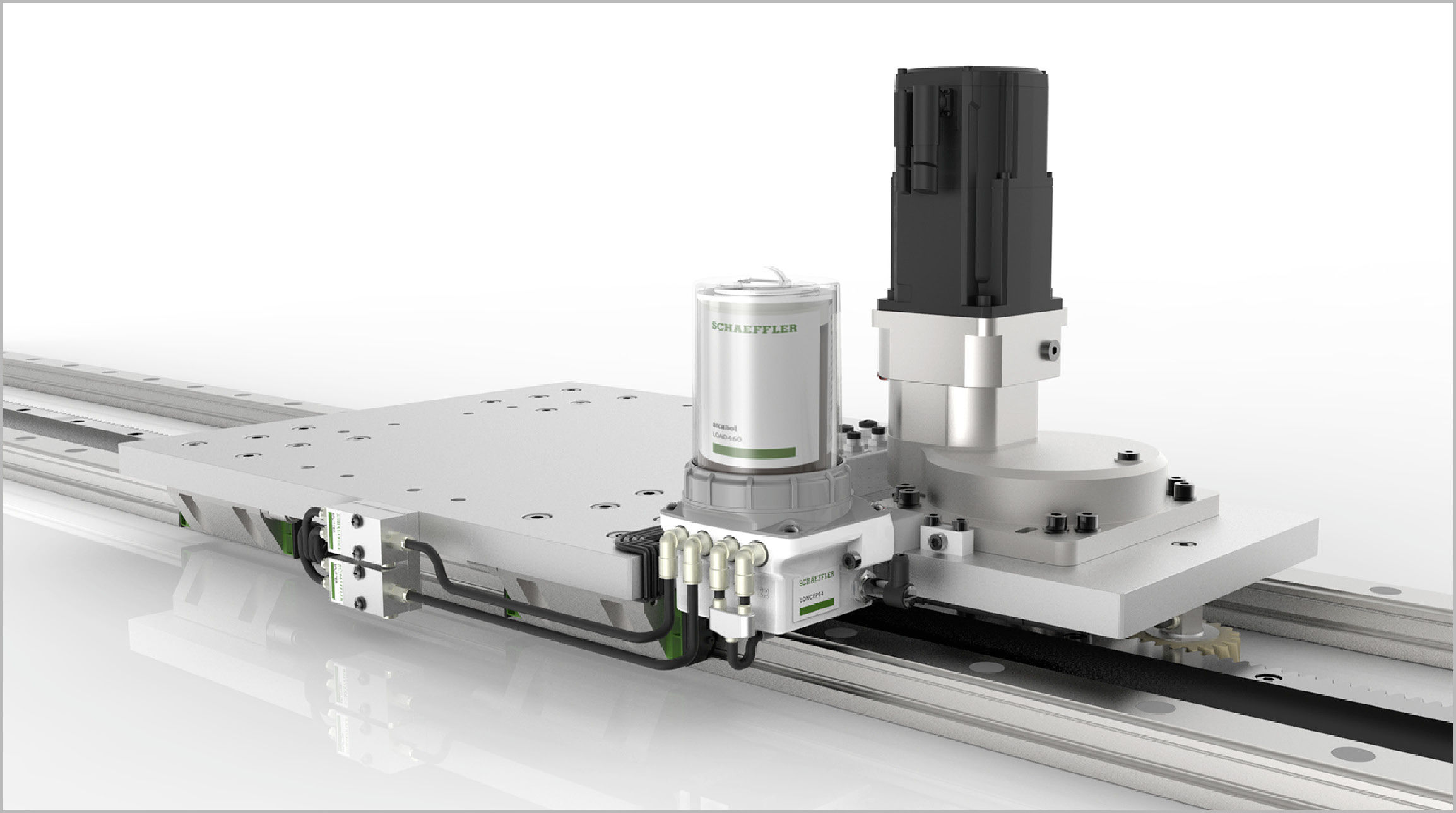

System components for robots

From standard components to individual solutions: Schaeffler with complete robotics portfolio. Within just a few

years, the automotive and industrial supplier Schaeffler has built up one of the most extensive portfolios for

industrial robotics. These include a PCB motor series for lightweight robots and cobots, two precision strain

wave gear series, a torque sensor system which is fully integrated into the strain wave gears, and, of course,

bearing solutions for swivel joints and gearboxes.

Read More

Robots of the latest generation

TM Robotics presents powerful SCARA series with a future-proof controller. TM Robotics, Shibaura Machine's

(Japan) sales and service partner for Europe, carries a comprehensive range of the latest industrial robots,

including the THE400, THE600, THL300 and SCARA model THP550.

Read More

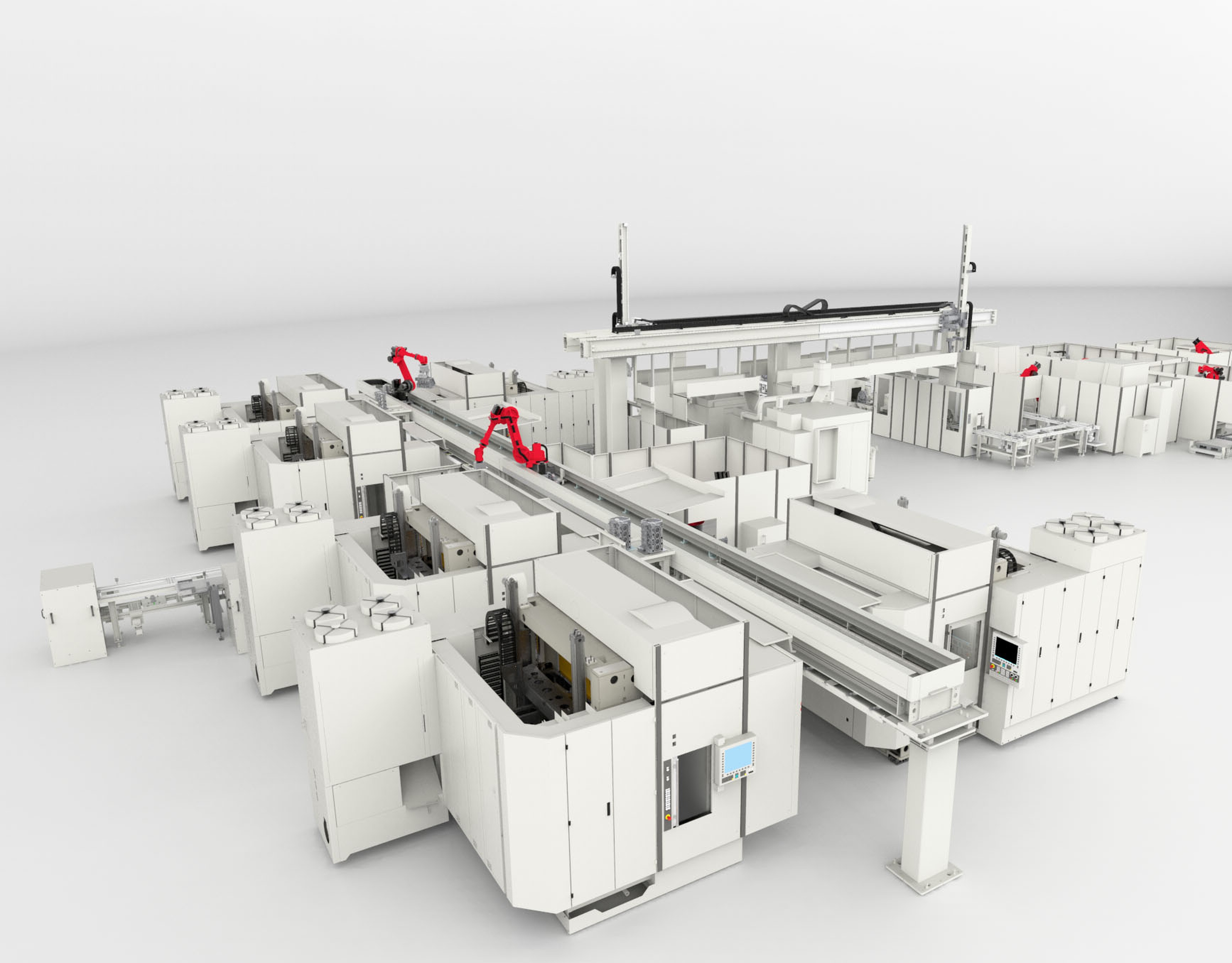

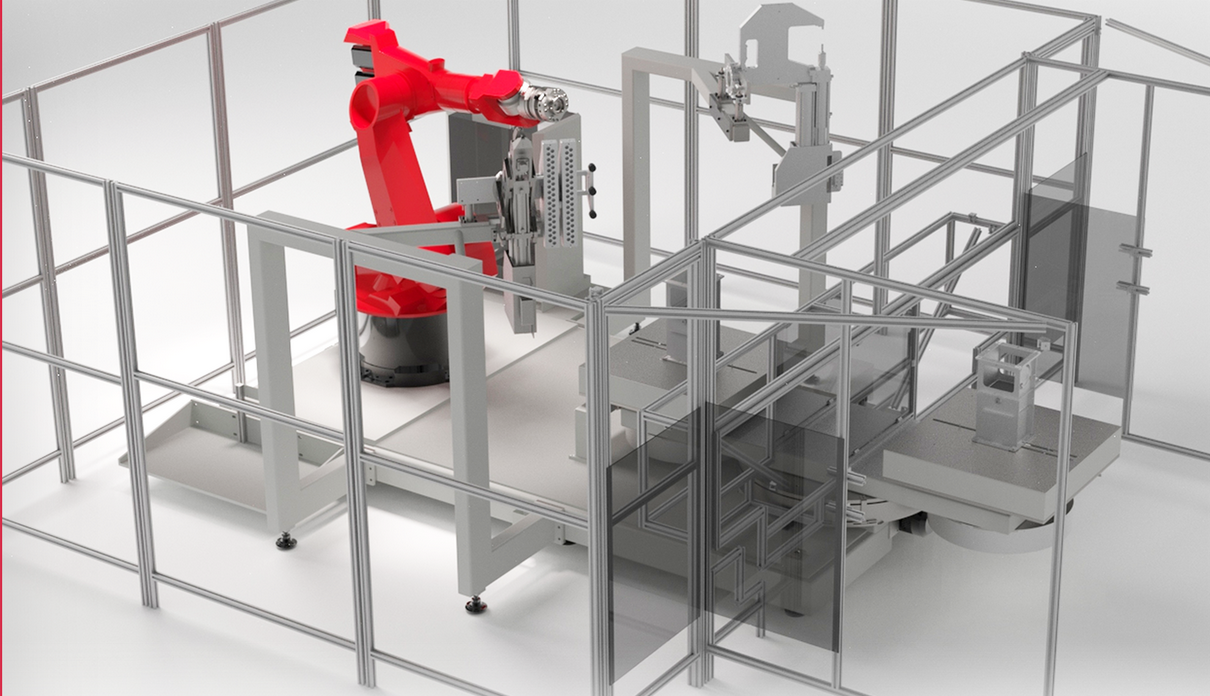

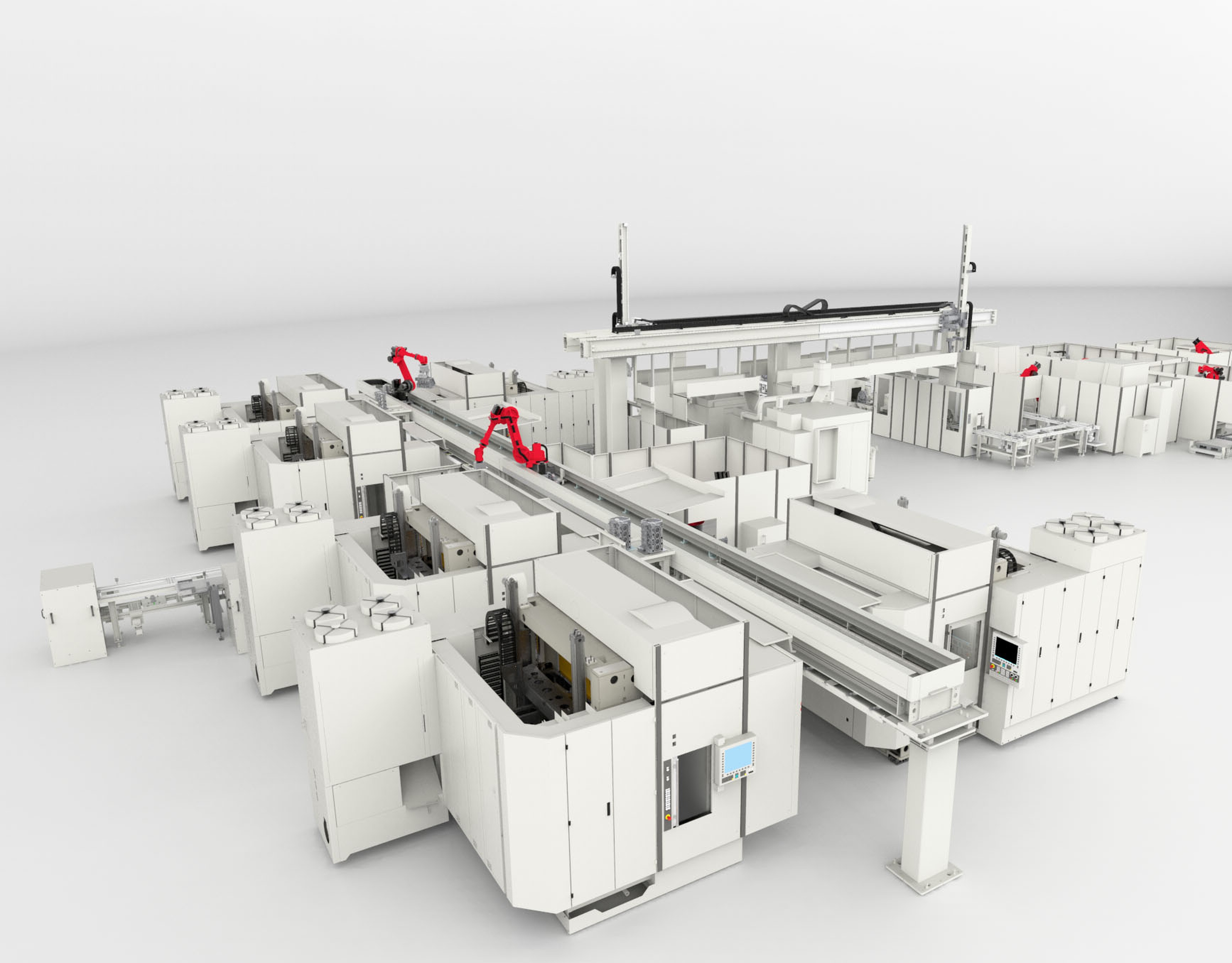

Reproducible quality and more efficiency through individual automation solutions in assembly

Pressing, joining, screwing, gluing, coating – SW Automation designs custom solutions for assembly automation

that increase efficiency in automotive manufacturing. Employees are deployed precisely where their flexibility

and intuition are indispensable.

Read More

More productivity and availability in manufacturing through digital services

A comprehensive range of digital services leads SW's customers into the digital age in a practical and

production-oriented manner. From this so-called life data portfolio, modules can be flexibly selected that best

support a company in achieving its individual goals – for example, increasing productivity. Data sovereignty

always remains with the customer.

Read More

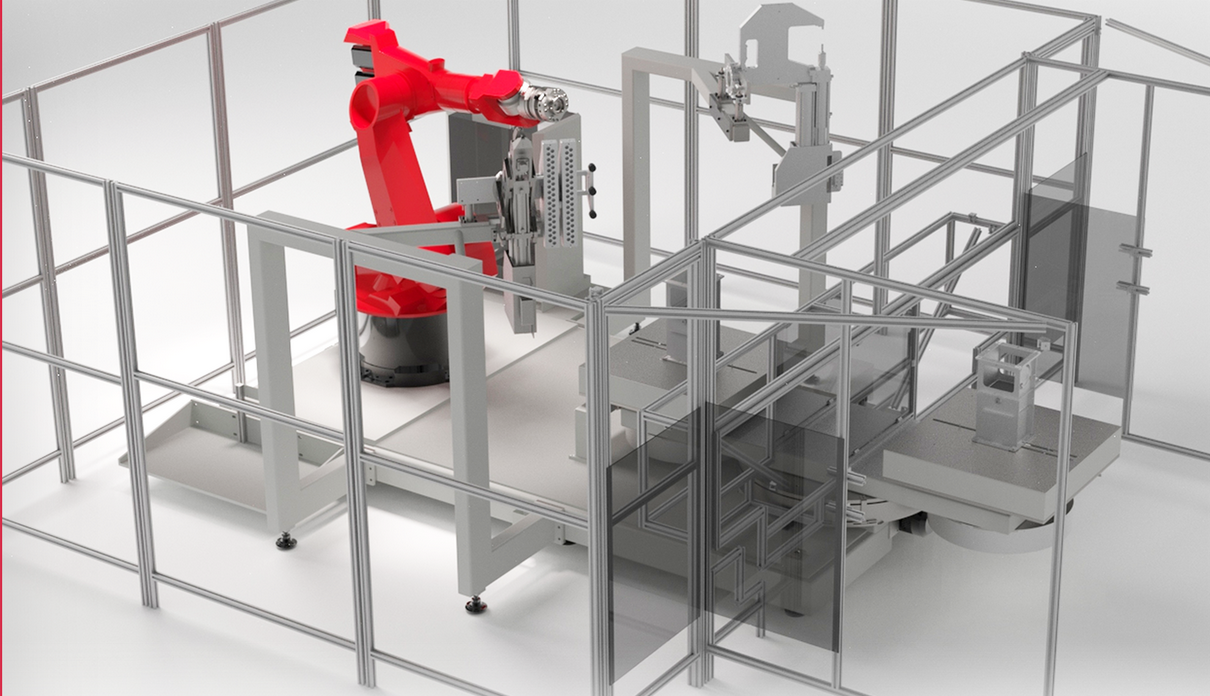

Modular automation in the automotive industry

Until now, it was common in the automotive industry to purchase an individual system for the automated

production of a specific product or workpiece. This investment paid for itself due to the plant and product

runtimes of almost ten years each. But the situation is increasingly changing. Production capacity utilisation

with a single product type produced in high volumes over a long period of time is only possible in rare cases.

Read More

New perspectives for factory automation

Bosch Rexroth develops Smart MechatroniX into a solution landscape and presents a world first for robots. Bosch

Rexroth continues to drive the digital transformation of linear motion technology and is further developing its

Smart MechatroniX platform. With new products and solutions, mechanical engineering and production companies can

increase their level of automation cost-effectively and simplify their system design at the same time. In

addition to the new Smart Function Kit Dispensing, Bosch...

Read More

Flexible automation solutions – modularly expandable, freely accessible and safe due to second level

With the automation modules from SW, CNC machining centres and peripheral stations can be optimally linked to

form highly productive production lines or operated in a matrix production.

Read More

Contactless angle measurement with camera‑based encoders

Visevi Robotics offers novel vision-based encoders ViseJoint now for generic angular measurement applications

without sensors on the joint. Measurement of one or multiple joints is performed remotely, using a computer

vision software and a camera that looks onto the joints from a distance. The solution can be used for smart

robots.

Read More

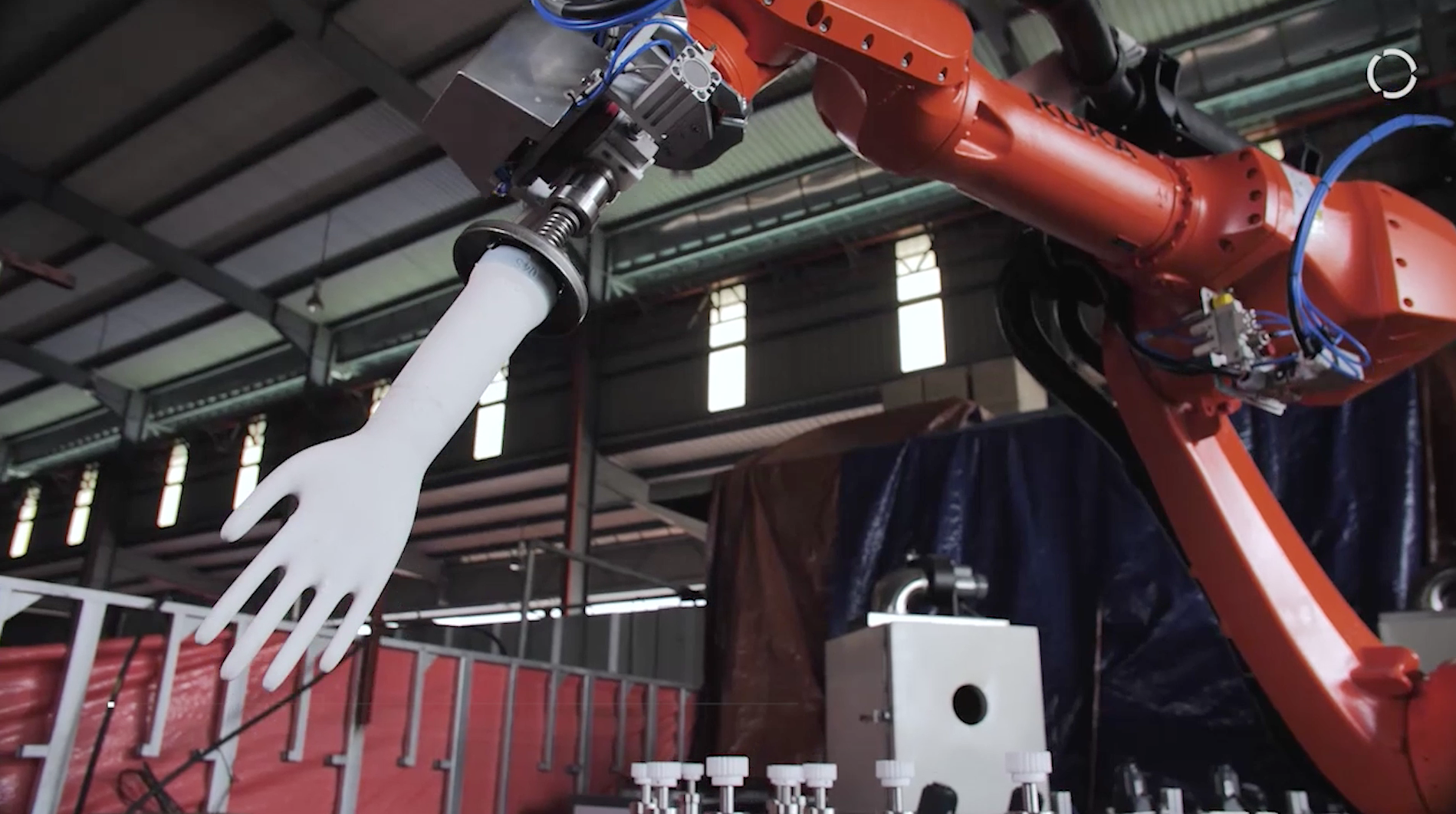

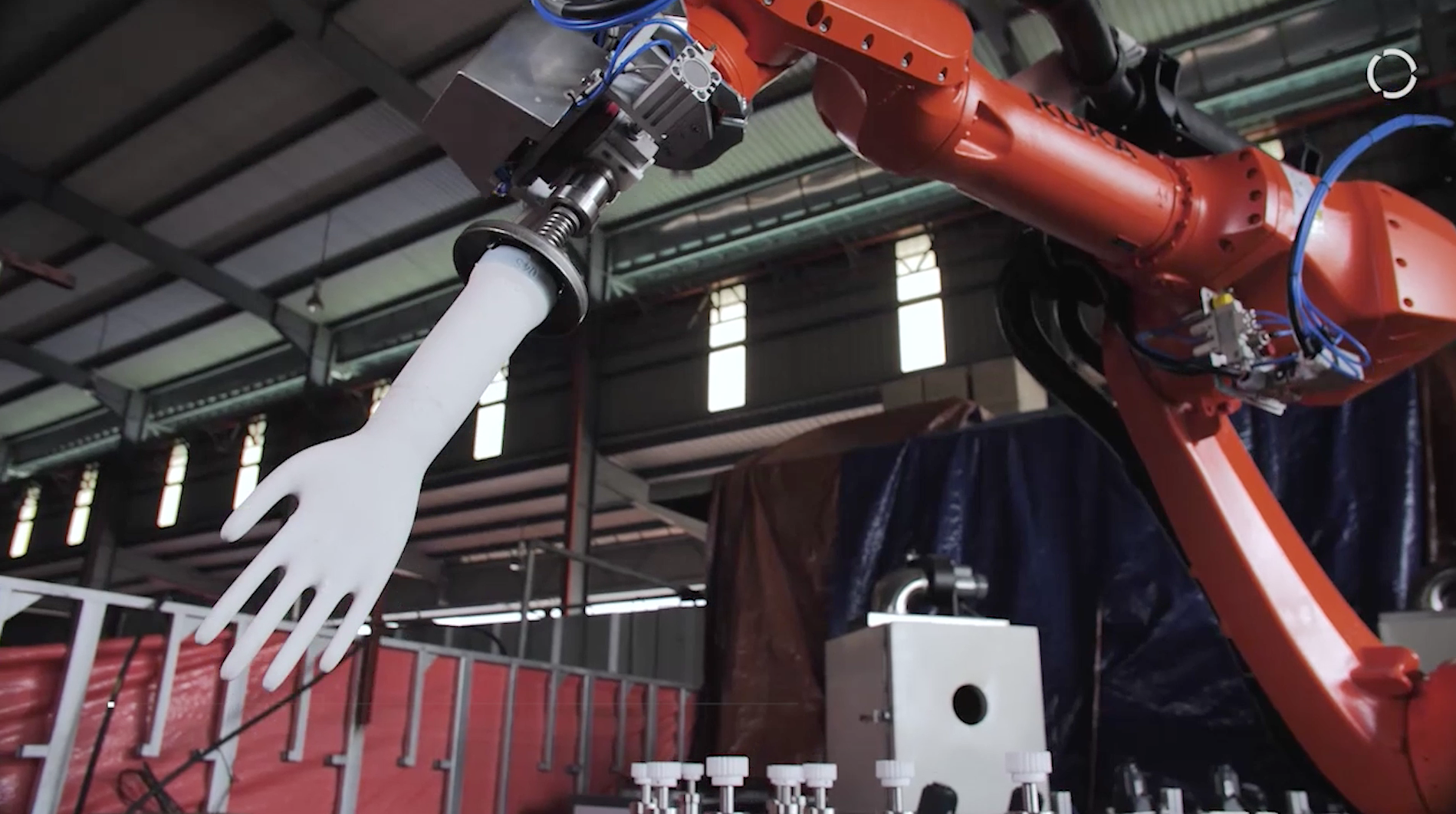

Automation in the blink of an eye

The development of rubber gloves is a lengthy process. Malaysian company Le Inoova has automated this process –

with the help of integrator IDEA and a KUKA robot. It now ensures greater precision and less waste.

Read More

Robot instead of muscle power

KUKA robots relieve the staff of a private brewer when palletising and depalletising beer crates. Small but

excellent – that’s the motto of the Christian Fiedler private brewery from the Saxon village of Oberscheibe.

With 18 employees, the family business is very successful in producing premium beers according to the

time-honored art of German brewing. A KUKA robot makes this work easier.

Read More

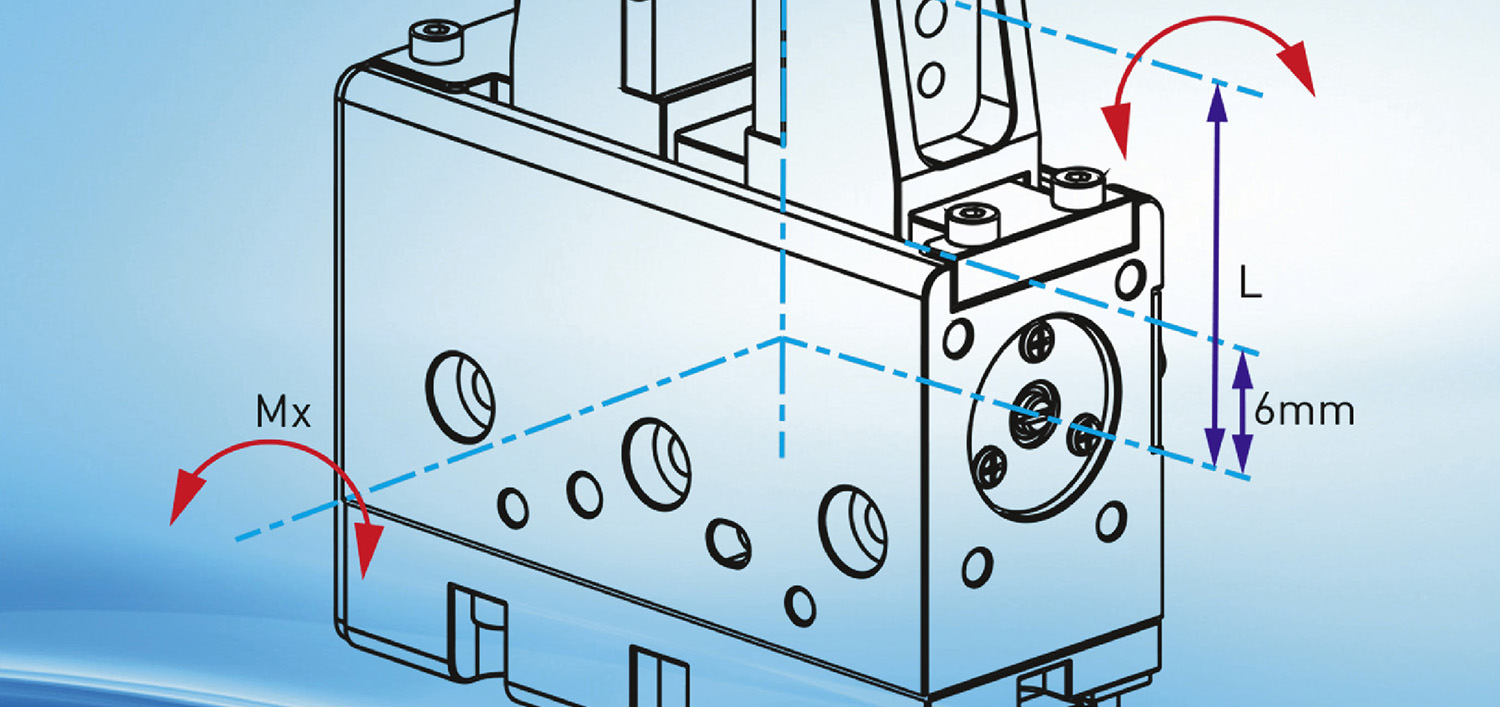

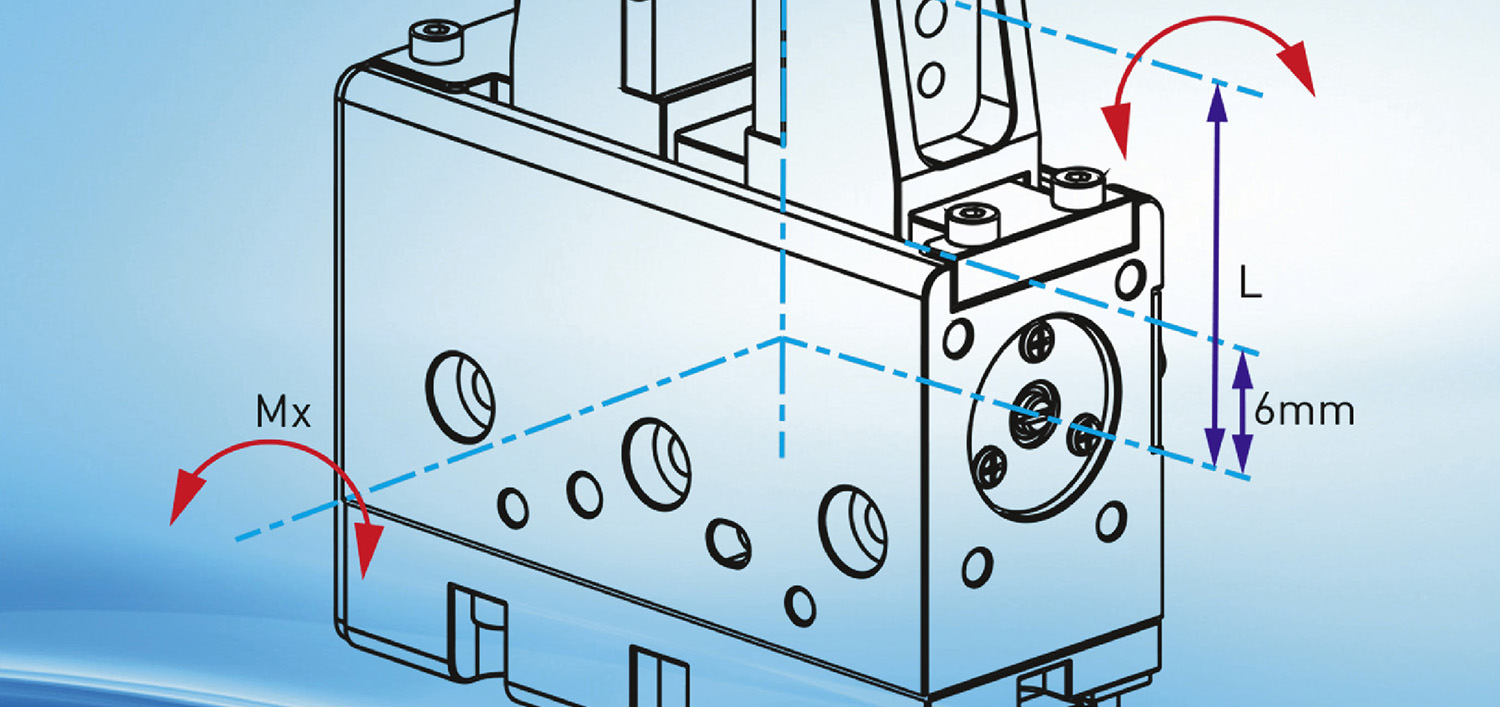

New mechatronic components for robotics and mechanical engineering

At sps 2021, which will take place from 23 to 25 November in Nuremberg, Dynetics will be presenting linear and

rotating servo motors from suppliers like NPM, Nidec and ELRA with drivers from Synapticon and a compact

electric gripper based on the world's smallest bidirectional ball screw from KSS at booth 490 in hall 4.

Read More

Mechatronic components for robot applications

At the Motek, Dynetics (booth 1220, hall 1) presents linear and rotary servo motors with drivers from

Synapticon, servo motors from NPM and a compact electric gripper based on the world's smallest bidirectional

ball screw from KSS.

Read More

Robots for everyone

Innovative robot teaching without programming efforts. It is no longer possible to imagine the industrial

environment without robots. They are the backbone of the smart factory. Increasingly, however, the digital

helpers can also be found in other environments. The Dresden-based company Wandelbots has now developed a

solution that makes the use of robots interesting for small and medium-sized companies in many industries. An

industrial PC from Kontron plays a central role in this setup.

Read More